Introduction #

Being known for my resourcefulness, I was asked to help solve a tricky problem. A local watch shop had quoted hundreds of pounds to replace the battery in a Breitling Navitimer World. The catch? They claimed it required a special tool to access the inside of the watch.

The Challenge #

A Complicated Watch Back Case #

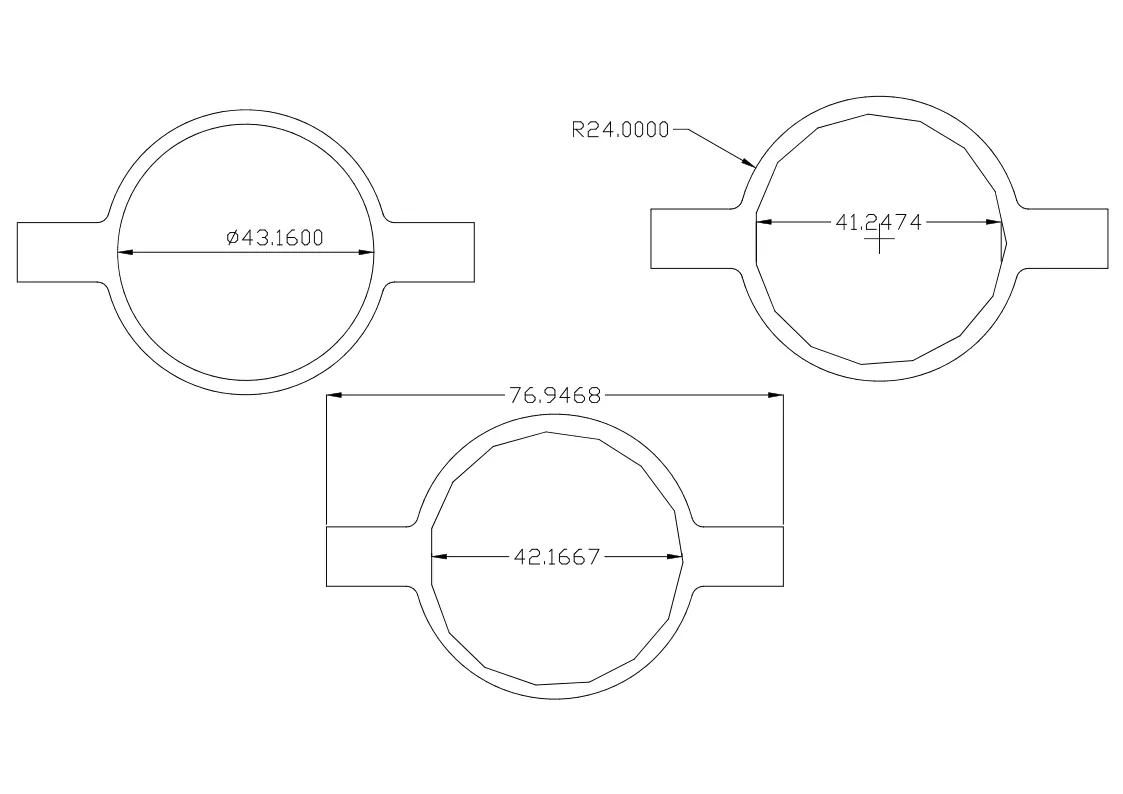

Upon examining the watch, I quickly identified the issue: the back case was composed of multiple layers of metal, each less than 1mm thick. Some layers were rounded, while others were chamfered, with varying dimensions throughout. To make things more complicated, the case’s intricate design made it impossible to simply pry open with basic tools.

The First Idea #

With access to a waterjet cutting machine, I figured I could design a custom tool to open the watch. The plan was simple enough: I scanned the back of the watch, loaded the image into CAD software, and traced each layer. Then, I added a 5mm ring around the traced path, along with two handles for better grip and leverage.

After testing the overall design & idea by cutting a test tool out of carbon fibre, I quickly realized this approach wasn’t going to be as easy as I thought. There wasn’t enough surface area on the case for the tool to grip effectively, and the precision required for the tool to work was more than I had resources for at the time. It was clear that this would need more trial and error to perfect.

The Struggle #

Not giving up, I tried a more direct approach—opening the watch by force. I pressed down with my thumbs in opposite directions, but the case wouldn’t budge. I even tried using a sticky note on the back of the watch to give my thumbs a better grip. Unfortunately, the additional grip didn’t make a difference.

To make matters worse, I had recently strained a flexor tendon in my hand, so my grip strength was weaker than usual.

The Solution #

Having a variety of rubber materials at my disposal, I tried various combinations between my fingers and the watch to gain more traction. Nothing seemed to work.

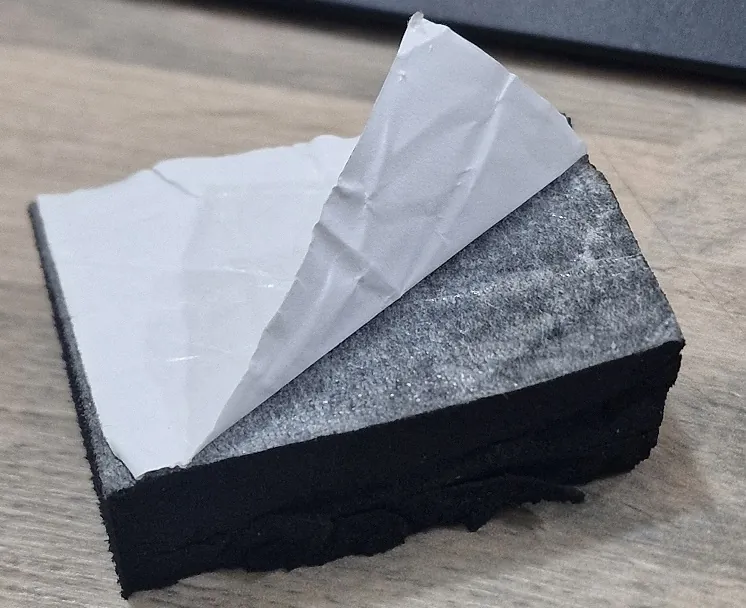

Then, I had a breakthrough idea. I grabbed a thick piece of sponge with a slightly adhesive backing. While the adhesive wasn’t very strong, it was enough to provide the right amount of friction. I placed the sponge on the back of the watch, holding the watch in my left palm and using my right palm to push and twist counterclockwise.

With just the right amount of grip, I was finally able to unlock the watch! Success!

Conclusion #

A Lesson in Persistence and Innovation #

What started as a seemingly impossible task ended with a resourceful solution. It wasn’t the smoothest process, but in the end, The battery was replaced without spending a fortune or relying on specialized tools. It was a great reminder that sometimes persistence, creativity, and a little trial and error are all you need to solve even the most complicated problems.